Silo Maintenance and Services

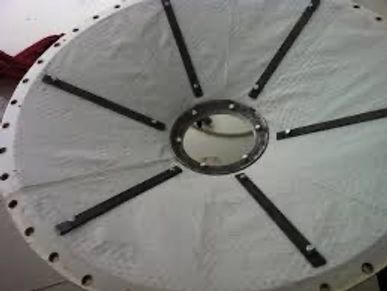

Fluidising Bed Replacement

Reverse Check Filters and Bag filters

Rotary Valve Service & Replacement

Your silo fluidising bed is a critical part of the silos operation. It allows the fluidising of the material for pneumatic conveying.

During the maintenance we offer.

- Full bed replacement with the offering of different micron sizes.

- Repairs to exiting beds, wether the cone or fluidizing bed.

- Full cone patch work if dented, damaged or welds have cracked.

Rotary Valve Service & Replacement

Reverse Check Filters and Bag filters

Rotary Valve Service & Replacement

The rotary valve is is an integral part of the silo feed. There are three general types of rotary valves, namely flow-through, blow-through and off-set, each suitable for various applications.

During the maintenance of the units we offer,

- Full replacements

- Refurbishment of existing, including air bearings and seals.

Reverse Check Filters and Bag filters

Reverse Check Filters and Bag filters

Reverse Check Filters and Bag filters

The filters on silo systems are another part of the silo that is critical for operation. they Regulate the pressure and allows the silo to breath. During the maintenance we can offer,

- Full change of filters.

- Full clean down and clean through with our portable filer cleaner.

- We inspect the air blowers and vibration unit for any inconsistencies.

- Full inspection of the blast panel and seals.

- We can also offer a full remote testing unit reducing the time an engineer is at height and will remotely alert you via text if there is an issue.

Pneumatic Blowers and Vacuums

Pneumatic Blowers and Vacuums

Reverse Check Filters and Bag filters

Without these pneumatic Blowers and Vacuums your silo systems are useless. These being the hart of the operation its critical these are free from dust intake, veins are inspected and the operational pressure is consistent.

- Full operational testing

- Vein/Fan inspection for ware or balance.

- All none return valves on the system for damage and or operation.

- Blow off valve pressure test for correct relief pressure.

Silo Cleaning Services

Pneumatic Blowers and Vacuums

Full inspection and Testing

Full roped access, with confined space certification. With part of our maintenance, services we offer on silos, cleaning is an integral part of the maintenance. to prevent build up, bridging and helps flow of the product.

All excess build up is taken away for disposal with each silo having a full inspection from top to bottom and a full service report supplied.

Full inspection and Testing

Pneumatic Blowers and Vacuums

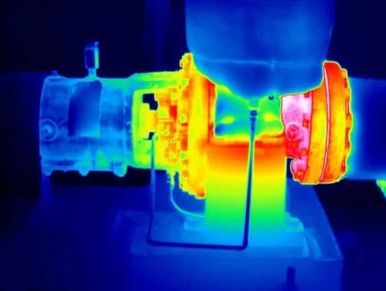

Full inspection and Testing

We provide a full range of inspection services for your silo's including full internal/external visual inspection, pressure / seal checks, thermal inspections. All designed to provide early early problem detection, increase quality,, minimise downtime and ultimately extend silo lifespan

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Derby Road, Draycott, Derby

DE72 3NX

Wyvern Engineering Services Ltd

Service@wyvernengineeringservices.com 07975 551550 & 07939 311446

Our Core Hours

Mon | 09:00 – 17:00 | |

Tue | 09:00 – 17:00 | |

Wed | 09:00 – 17:00 | |

Thu | 09:00 – 17:00 | |

Fri | 09:00 – 17:00 | |

Sat | Closed | |

Sun | Closed |